Our scrubber systems are known for safety and quality

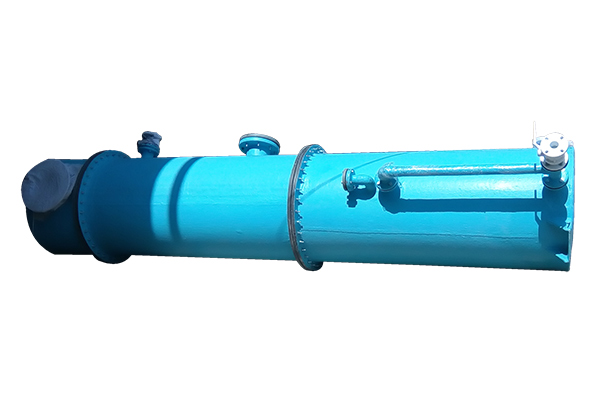

We are one of the foremost manufacturers providing unsurpassed solutions associated with the air pollution control system in terms of the scrubber system made of the FRP material to reap its unique characteristics and advantages including low production cost, design flexibility and superior strength to weight ration. Besides that, it is also well known for its remarkable resistivity against corrosion and high temperature.

This FRP scrubber system is a fantastic solution for the highly corrosive environments, designed and manufactured owing the area of application and nature of the gas in order to reap highest of the material and hence deliver high performance at the lower cost.

The use of the finest quality FRP thermoplastic together with our quality controlled processes facilitate us to produce an FRP scrubber system that is a paragon of the precision engineering and quality engineering. Our FRP scrubber system covers scrubbing vessel, ductwork, fan system, mist eliminator, pumping and an exhaust stack, in which mist eliminator is detached if it is a dry scrubber system.This FRP scrubber system we provide in the diversified range of the specification as well as provide as per the drawings and specification given by the clientele. The use of the advanced German welding technology for sealing enable us to deliver a range that conforms to the DVS standards, whereas strict quality control has enabled us to deliver both ranges of the FRP scrubber system strongly conforms to the ISO 9001:2008 standards. This FRP scrubber system is guaranteed to fulfill your requirements and surpass your expectations too.

Advantageous side of our FRP Scrubber System:

- Considerable corrosion resistance

- Virtually no requirement of maintenance

- Rugged construction bestow longer lifetime

- Light weight ensures easy installation

- Very high strength, yet available at half of steel price

- Excellent shock resistance

- Environmentally friendly

- fire retardant ensures safety personnel

- Maximum UV resistance

Application Scope of FRP Scrubber System:

Corn Processing Facilities, Petroleum Refineries, Chemical Processes, Acid Manufacturing Plants Food Manufacturing, Machining and Grinding Exhaust, Fiberglass & Composite Industries, Utility Boilers, Foundries and Metal Finishing Operations.

Different alternatives in FRP Scrubber System:

- PP FRP Scrubber System

- FRP Scrubber System

- GRP SCRUBBER System

- HDPE Scrubber System

- PPH FRP Scrubber System

- PPH Scrubber System

FRP Scrubber System is available for :

- Wet Scrubber System

- Dry Scrubber System

- Chlorine Scrubber System

- Fume scrubber system

- Gas scrubber system

Our Specialized Product Range

- Industrial Storage Tanks

- Industrial Scrubber Systems

- Centrifugal Blowers

- FRP Gratings / Fiber Glass Gratings